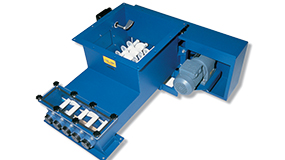

ProMinent® Multiscrew Feeders

For Safe Discharge and Accurate Metering of Solids

The ProMinent® Multiscrew Feeder is the core of all ProMinent® dry feed packages. Application specific systems are available to satisfy the dry feed handling, mixing, delivering and controlling requirements for all of your dry feed needs in both the Municipal and Industrial market place. With unique construction, ProMinent® Multiscrew Feeders are outstandingly suitable as metering devices for both granular and arch-forming materials.

Request more info

Benefits

- Multi screw design

- High metering accuracy

- Linear discharge curve

- Forced discharge

- Self-cleaning feeder screws

- Large active contact area

- Robust low-wear construction

High Metering Accuracy

A number of interacting counter rotating feeder screws are able to create blocking zones between them. This ensures extremely high accuracy as the screws are self-cleaning

Linear Discharge Curve

The discharge curve is linear. In conjunction with speed and discharge per time.

Assuming the material has constant volume weight, the accuracy will be better than +/- 1%. This enables both batch and continuous processes to be accurately controlled.

Safe Product Discharge

ProMinents®’s multiscrew design ensures that material is discharged over the entire active area of the feeder. This prevents the material from bridging and ensures that the principle of “first in, first out” is maintained.

Optional level monitoring is available to detect arch build-ups for extremely arch-forming materials. This will activate an arch breaking system.

Example of Typical Materials

- Lime

- Polymer

- Potassium Permanganate

- Urea

- Bentonite

- Aluminium Sulfate

| Technical Data/Dimensions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeder Type | 182 | 224 | 302 | 403 | 405 | 475 | 624 | 626 | 627 | 1004 | 1254 |

| A | 7.09 | 8.66 | 11.81 | 15.75 | 15.75 | 27.56 / 15.75 | 24.41 | 24.41 | 24.41 | 39.37 | 49.21 |

| D | 13.39 | 16.14 | 22.64 | 39.17 | 24.61 | 30.51 | 41.04 / 47.64 | 28.54 | 28.54 | 58.46 | 77.76 |

| E | 8.46 | 12.2 | 12.99 | 20.87 | 14.96 | 14.94 | 21.26 | 19.09 | 16.34 | 24.41 | 29.33 |

| F | 10.24 | 12.8 | 17.72 | 31.5 | 19.69 | 25.59 | 32.36 / 39.37 | 23.62 | 23.62 | 48.23 | 65.04 |

| G | 11.81 | 14.57 | 17.72 | 25.98 | 21.65 | 21.65 | 29.92 | 25.98 | 25.98 | 38.58 | 44.69 |

| H | 10.43 | 14.17 | 17.32 | 24.02 | 18.11 | 17.32 | 22.83 | 22.05 | 18.31 | 25 | 30.91 |

| J | 10.83 | 10.71 | 13.78 | 21.06 | 18.11 | 21.65 | 23.23 | 20.87 | 23.62 | 38.58 | 42.32 |

| L | 2.36 | 3.15 | 3.94 | 7.87 | 3.94 | 3.94 | 7.87 | 3.94 | 3.94 | 11.02 | 13.78 |

| O | 4.72 | 8.66 | 7.09 | 17.17 | 15.75 | 15.75 | 24.41 | 2 x 9.06 | 24.41 | 39.37 | 49.21 |

| No. of Screws | 2 | 4 | 2 | 3 | 5 | 5 | 4 | 2 x 3 | 7 | 4 | 4 |

| Max Cap lbs/min | 1.8 | 29.4 | 73 | 529.5 | 176.5 | 176.5 | 735 | 2 x 132 | 294 | 2647 | 6472 |

| *All measurements in inches unless otherwise noted | |||||||||||

| ** All rates based on 50lbs/cu3 bulk density | |||||||||||