Three Stage Polymer System Results in Significant Saving

Less polymer, less maintenance, less down time from new polymer feed systems. A cost-effective solution for increased plant efficiency.

System Overview

The Capital of Montana, Helena, is currently home to two potable water treatment plants that serve roughly 35,000 residents, the Ten Mile Water Treatment Plant, and the Missouri River Treatment Plant. The Ten Mile Water Treatment Plant is currently used as the main supply plant for the City of Helena’s potable water production, with the Missouri River Treatment Plant operating intermittently to supplement seasonal demand.

Helena’s municipal water system draws from numerous snowmelt and watershed resources – Chessman Reservoir, Scott Reservoir, Ten Mile Creek, Beaver Creek, Minnehaha Creek, Moose Creek, Walker Creek, and two wells. A total watershed over 30 square miles - creating highly variable temperatures and turbidities.

|

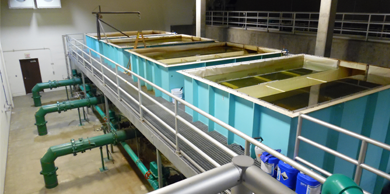

The Ten Mile Water Treatment Plant, originally constructed in 1991, is a gravity feed, traditional filtration drinking water plant, with a throughput of 2.8 - 8.0 million gallons a day. Their treatment process includes chemical addition for flocculation, four contact adsorption clarifiers, four standing baffle multimedia filters with surface wash, and liquid chlorine disinfection. The plant has two clear wells, including a 50,000-gallon interior pump clear well and a 6,000,000-gallon exterior finished water clear well. Finished water is conveyed to the City of Helena via a five-mile-long gravity feed pipeline.

|

The Polymer Challenges

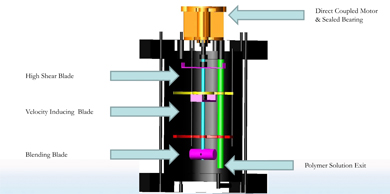

In addition to updating their aged chemical dosing infrastructure with pre-engineered skid systems, Ten Mile Water Treatment Plant staff elected to install two new polymer blending systems that provide efficient polymer activation through a mechanical three stage mixing chamber. The existing hydrodynamic, or static, means of polymer activation had poor mixing and inadequate activation, in the short run prior to the plant’s clarifiers. The plant was utilizing more cationic polymer than comparably sized treatment plants.

Results of Three Stage Mixing

Since implementing the new three stage mixing system, the facility has observed a sharp decrease in their polymer consumption, a measured reduction of between thirty to forty percent. This has not only reduced the cost associated with the polymer but has also realized several other benefits including longer filter runs. Traditionally, filter runs would have been 100 hours, operations personnel have been able to extend this to 140 hours. There has also been a reduction in filter waste time, and reduction in head loss. The ProMinent ProMix® three stage mixing system operates with three distinct mixing zones to ensure optimal activation of neat polymer. The first stage is a high energy mixing that eliminates any of the agglomeration that often takes place during initial wetting; in the second stage of the mixing chamber, a reduced energy mixing allows for elongation of the polymer chains without damage; and the third mixing stage features a very gentle mixing that ensures maximum activation and homogenization prior to the systems discharge.

|

Plant management states that the ProMinent ProMix® systems would have paid for themselves via the reduction in polymer usage over the course of their first year in use, had it not been for inflationary increases in the cost of the neat polymer itself. Plant management and operations have expressed how pleased they are with the equipment’s performance, and the efficiencies that have culminated since the equipment’s implementation.

Written in conjunction with ProMinent distributor, Advanced Pump & Equipment, and the City of Helena Water Production. Copyright 2022 - ProMinent Fluid Controls, Inc. - All rights reserved

CLICK HERE to download the pdf version