Treatment Plant Saves $120,000 Annually Using New Polymer Preparation & Feed System

The Foxwoods WWTP has slashed annual polymer costs by approximately two-thirds by switching to an in-line polymer preparation and feed system featuring an optimized mechanical design.

The Mashantucket Pequot Tribal Nation Wastewater Treatment Plant in Connecticut serves the Mashantucket Pequot Tribal Nation reservation and the Foxwoods Resort and Casino, including the MGM Grand at Foxwoods. The 3.6 MGD treatment plant has average daily flows of approximately 1 MGD during the week and up to 1.3 MGD on weekends.

The last plant expansion was made in 2008 to accommodate the expansion of the Foxwoods Resort and Casino, specifically the 900-room MGM Grand. The activated sludge plant runs two SBRs (sequencing batch reactors). After degritting and screening, wastewater flows directly into the SBRs followed by oxidation and extended aeration.

|

Dewatering Operations

The plant has approximately 150,000 gallons of aerated storage capacity that operators waste into daily. The solids are then dewatered through two high speed centrifuges. “We’re looking at anywhere from ¾ to 1 percent dry solids going into our centrifuges and average 20 percent dry solids coming out,” says Plant Manager David Drobiak. “We run the centrifuges every day – two shifts per day during the week and one shift per day on weekends. If we had a larger holding area for our biosolids, we wouldn’t have to run the centrifuges as much as we do, but we waste 40,000 to 50,000 gallons a day,” Drobiak says. “With only 150,000 gallons of storage, we have to keep it moving.” On average, the plant ships out two 15-ton roll-off containers of dewatered biosolids each week.

The plant’s high speed centrifuges are operated to obtain maximum solids concentrations while maintaining a 95 percent solids capture. Operators adjust the solids feed rate, polymer dosage, and differential speed to optimize dewatering performance. Centrifuge performance is evaluated during operation by sampling the centrate stream and cake solids. The responsibilities of the plant’s centrifuge operators include polymer mixing, dosing and monitoring usage, plus observing the feed and cake and making any necessary adjustments.

|

Polymer Expenditures Spike

In dewatering operations, biosolids must be conditioned with polymer to ensure optimum performance of the centrifuges. The polymer should be mixed correctly, because turbulent conditions can sheer the floc, thereby minimizing the polymer’s effectiveness plus insufficient mixing creates “fisheyes” that provide little value for flocculation. Polymer dilution and aging systems should be properly designed to optimize polymer usage.

After completion of the 2008 plant expansion, polymer consumption became very expensive. Three 275-gallon polymer totes were required every month for dewatering operations.

Due to the high cost, plant management began looking for ways to reduce polymer usage. Eventually a ProMinent ProMix M Series polymer preparation and feed system was brought in for a performance trial, comparing it to one of the plant’s polymer systems that had been operating for a number of years and featured a widely-used mechanical design.

Polymer Preparation: The Basics

Polymer preparation is a critical component in the biosolids handling process. Unless polymer preparation is completed properly, excessive polymer will be needed to provide adequate liquid/solid separation.

In polymer preparation, the first moment of initial wetting of polymer with water is most critical because of the high tendency to form large agglomerations of polymer(fisheyes). Employing very high shear for very short time period is required to prevent fisheye formation at this stage.

Once successful initial wetting is achieved, individual polymer molecules gradually dissolve into homogeneous solution. However, the extended or fully dissolved polymer solution is susceptible to any high shear. Because the polymer chain consists of very weak carbon- carbon bonds, a considerable amount of polymer chains may be easily broken during the activation process when the extended polymer molecules remain in the high shear environment.

Two-Thirds Polymer Reduction

The difference in polymer consumption with the ProMix unit compared to the plant’s existing systems was so significant during the performance trial that management was prompted to quickly switch out the existing units with ProMix polymer preparation and feed systems.

“We reduced our polymer usage by about two-thirds after switching to the ProMinent units,” Drobiak says. “Last year our polymer budget was approximately $180,000, but we ended up spending only about $60,000. We had been ordering three 275-gallon polymer totes per month, but we now only order that amount every quarter. Plus, the biosolids coming out of our centrifuges still average 20 percent dry solids.”

|

Three-Zone Polymer Preparation

This significant reduction in polymer usage at the plant can be attributed to the fact that the new ProMix systems installed there are designed with three specific zones of polymer activation, whereas the plant’s previous units had only two zones.

The first polymer activation zone provides high mixing energy to achieve the successful initial wetting of the polymer to prevent fisheye formation. The second zone provides medium mixing energy to provide optimum mixing without damaging the expanding polymer chains that have been activated and are very fragile at this stage. The third zone reduces the mixing energy even further, providing very gentle mixing to ensure that the polymer solution becomes fully homogeneous. The three-zone activation regime also provides for slightly longer retention time prior to use.

|

Automation & Control

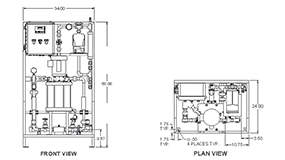

The Prominent ProMix M Series polymer preparation and feed system provides LCD display (including primary and secondary flow display) with touchpad control, remote start/stop and programmable auto-flush, and the unit maintains desired concentration based on primary and secondary dilution water flow.

The ProMix system is engineered to meet liquid polymer feed applications utilizing diaphragm or progressive cavity pump technologies. It also provides 4-20mA input to pace the pump as well as provides connections for Ethernet communications and datalogging.

Quick ROI

Switching from a two-stage mixing system to an enhanced three-stage polymer activation regime has optimized polymer use significantly at the Foxwoods WWTP. This has, in turn, greatly improved the overall biosolids management program for the facility. Plus, the extensive polymer savings essentially provided the facility a return on its investment in less than two months.

About the Author:

Stephen Roach works for Wescor Associates, Inc. in Wrentham, MA. Wescor Associates is an authorized distributor for ProMinent Fluid Controls, Inc.

CLICK HERE to download the pdf version