Dry Feed Solutions

PolyRex is a complete polymer feed and mixing system for preparing dry or liquid polymers. The PolyRex system includes a dual feed screw volumetric feeder for accurate polymer delivery, a wetting/dispersion mixer to effectively disperse the polymer into solution, a low shear mixing/aging tank and solution feed tank. Larger systems, shown in the photo, utilize tandem mix tanks for increased capacity.

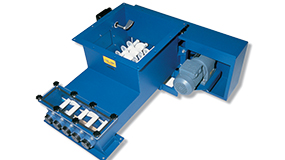

PolyRex Stacked Tank System

The volumetric feeder hopper is filled dry polymer utilizing the vacuum loader. The vacuum filter prevents dusting when loading the hopper. The dry polymer is then accurately delivered by the volumetric feeder into the initial wetting/mixing unit where all the dry particles are hydrated without creating fish-eyes. The solution then flows to the upper mixing/aging tank. The mixing tank is designed for low shear agitation, utilizing large mixing blades and low RPM, to gently mix the solution without shearing the fragile polymer molecules. Once the solution has been mixed/aged, the transfer valve will allow the solution to gravity flow into the lower feed tank, where it can be pumped to the process.

The PolyRex system can also be used for mixing emulsion/dispersion liquid polymers.

An Allen Bradley PLC automatically controls the system.

A PolyRex system has the following components:

- Dry polymer storage hopper and vacuum hopper loader, including bag filter to prevent dusting.

- Dual screw volumetric feeder to accurately meter dry polymer.

- Wetting cone to evenly disperse, mix and hydrate all the dry particles, preventing agglomerations.

- Stainless steel mixing tank designed for low shear agitation, utilizing large mixing blades and low RPM, to gently mix the solution without shearing the fragile polymer molecules.

- Stainless steel storage/feed tank.

- Final feed metering pumps to feed the polymer solution to the process can also be provided.

- Control panel with Allen Bradley PLC/HMI for complete automatic control of the system.

- Capacities up to 75 lb/hr

PolyRex Polymer Feed System

Integrated Dry / Liquid Polymer Feed System

The PolyRexis a complete automatic feed system for batch preparation and metering of solutions from dry or liquid polymers.

PolyRex delivers an adjustable flow of dry or liquid polymers into the desired dilution water, and uses a step-by-step mixing system to effectively hydrate and mix the polymer to a homogenous and activated polymer solution. The initial step is the hydration system, where the polymer is initially wetted, followed by water acceleration in the ejector, and the efficient but gentle agitating in the mixing tank. The PolyRex step-by-step mixing system provides you with the most efficient way to produce a polymer solution. (...more)

Features & Benefits

- Dry or liquid polymer feeder

- Choice of hydration systems

- Automatic water control

- Mix/feed tanks in various sizes

- User friendly control logic

- Proven accuracy with dual screw volumetric feeder technology

- Feeder discharge valve to prevent moisture from reaching the dry polymer

- Heated wetting area, which prevents condensation.

- Highly effective static mixer

- Vacuum conveyer option

- Variety of hoppers and bulk bag handling systems

- Modular, Compact, Reliable design

PolyRex Optimo Polymer Wetting System

Wetting system

The ProMinent® Optimo wetting system is adapted for very high efficiency of polymer mixing. The unique construction has been developed especially for customers with high demands.

Optimo consists of a closed initial wetting system with mechanical mixing for highest possible efficiency. This closed system along with the accuracy of the dual screw volumetric feeder results in an accurate, reliable and dust free preparation of polymer solutions. Optimo in combination with the ProMinent® PolyRex provides a complete system that offers clear polymer solution with minimal polymer consumption. (...more)

Features & Benefits

- Dry or liquid polymer feeder

- Automatic water control

- Mix/feed tanks in various sizes

- User friendly control logic

- Proven accuracy with dual screw volumetric feeder technology

- Feeder discharge valve to prevent moisture from reaching the dry polymer

- Heated wetting area, which prevents condensation.

- Suitable for use with both high and low water pressure

- Superior mixing that guarantees both clear solutions and minimal polymer consumption

- Vacuum conveyer option

- Variety of hoppers and bulk bag handling systems

- Modular, Compact, Reliable design

ProMdry Dry Chemical Feed System

Compact Dry Chemical Feed Package

The ProMdry system is designed to mix dry chemicals into solution prior to adding to the water treatment process. The volumetric feeder dispenses dry chemical into the mix tank while the flow switch is monitoring water entering the mix tank. The dry chemical and the water are introduced directly into the prop style tank mixer, where they are mixed into solution. The solution is then drawn from the opposite side of the tank to the process.(...more)

For Safe Discharge and Accurate Metering of Solids

The Multiscrew Feeder is the core of all ProMinent® dry feed packages. Application specific systems are available to satisfy the dry feed handling, mixing, delivering and controlling requirements for all of your dry feed needs in both the Municipal and Industrial market place.

With unique construction, Multiscrew Feeders are outstandingly suitable as metering devices for both granular and arch-forming materials. (...more)